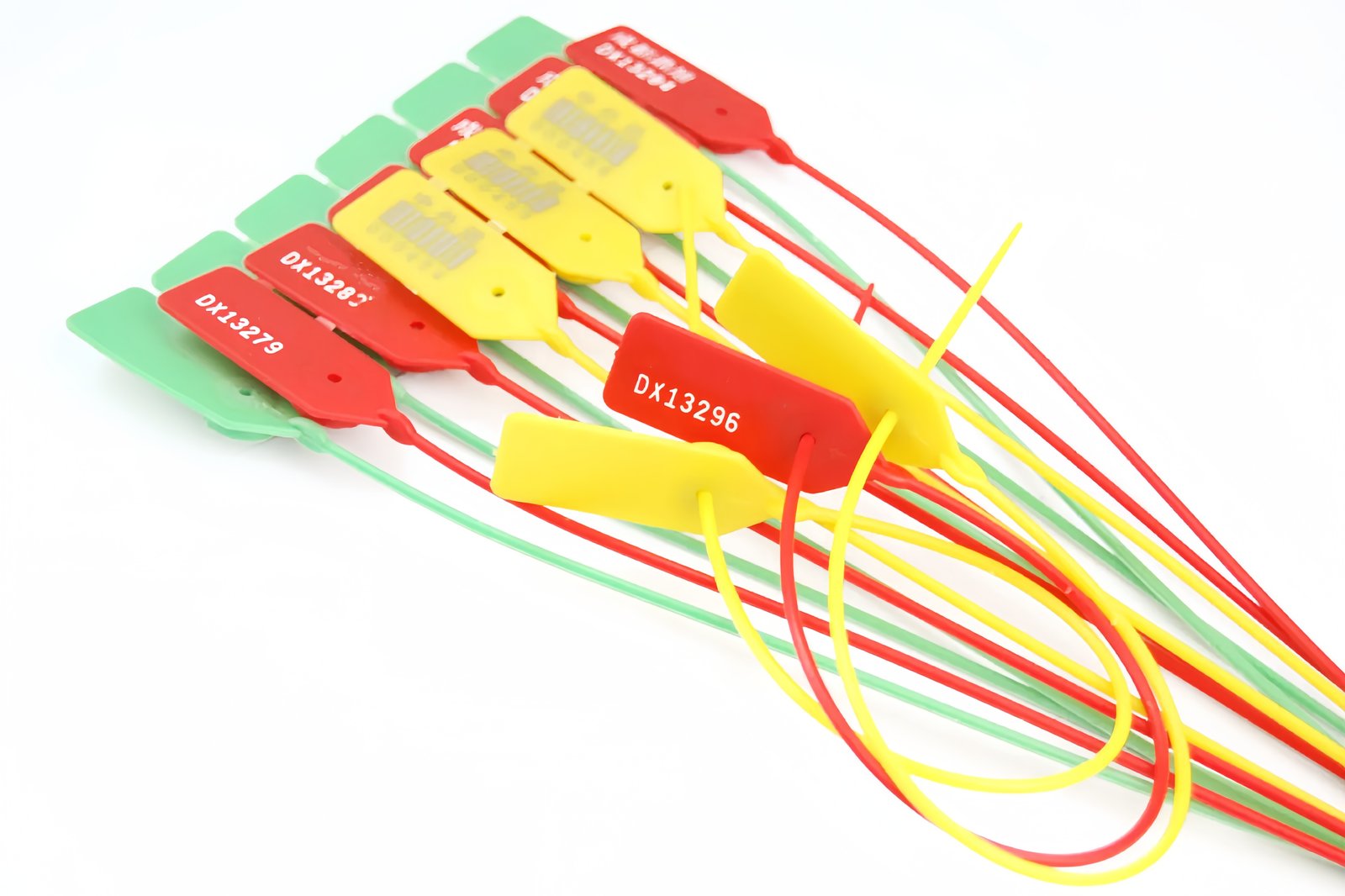

Plastic seals, primarily made of PP (Polypropylene), are versatile plastic products used in everything from luxury goods to everyday household items. Cable ties, on the other hand, are typically made from PA66 (Nylon) and share some similarities with plastic seals. However, as society has progressed, these two items have developed distinct differences.

A comparison of the shapes and sizes of plastic seals and cable ties reveals some key variations. When it comes to cost considerations, plastic seals generally use PP due to its affordability, while cable ties often employ nylon PA66, balancing cost with the need for strength. Let’s delve into the specifics of each.

In conclusion, the best product is the one that suits your needs. Whether it’s a plastic seal or a cable tie, the key is finding what is comfortable and appropriate for your specific use.