Setting up a nylon cable tie production plant involves several steps and requires various types of machinery. Here’s a general overview of the key equipment and machinery you would need:

Injection Molding Machine:

This is the core machine for manufacturing nylon cable ties. The injection molding process involves melting plastic granules and injecting them into a mold under high pressure to form the cable ties. You’ll need to choose a machine based on the desired production capacity and the size of the cable ties.

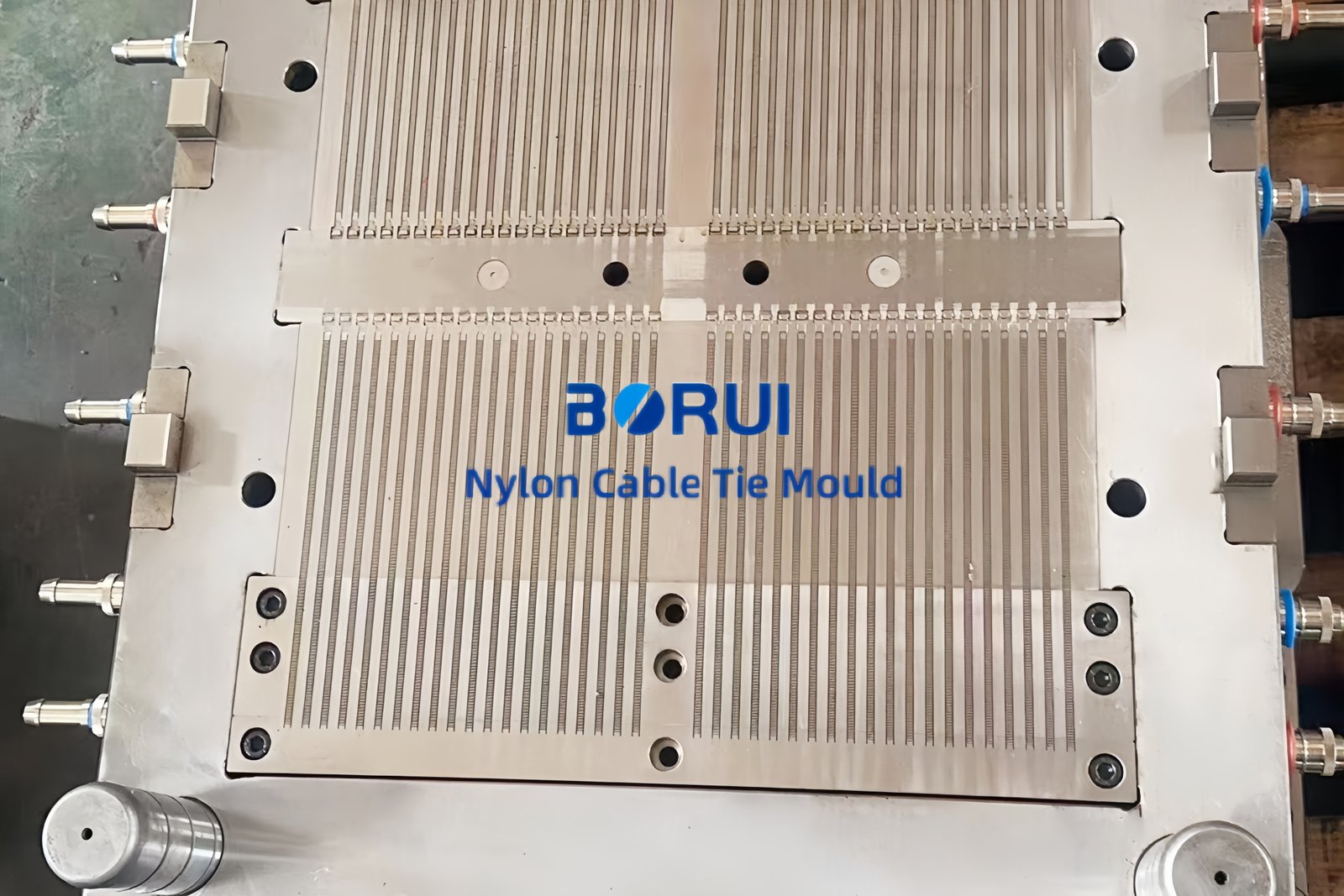

Cable Tie Molds:

The molds are crucial for shaping the nylon cable ties. They are fitted into the injection molding machine. The design and quality of the molds determine the precision and quality of the cable ties.

Raw Material Mixer:

Nylon granules are the primary raw material for cable ties. A mixer is used to blend the nylon granules with other additives or colorants evenly before they are fed into the injection molding machine.

Chiller:

Injection molding generates a lot of heat, which needs to be controlled to ensure product quality. A chiller system is used to cool down the molds quickly after each injection cycle.

Granulator or Crusher:

This machine is used for recycling scrap or defective products. It crushes them into small granules which can be reused in the production process.

Quality Control and Inspection Equipment:

To ensure the quality of the cable ties, you’ll need various testing and inspection equipment. This may include tensile strength testers, thickness gauges, and visual inspection systems.

Packaging Machine:

Once the cable ties are manufactured and inspected, they need to be packaged. An automated packaging machine can help in efficiently packing the cable ties for shipment.

Auxiliary Equipment:

This might include air compressors, dryers for drying the raw material, and other supportive machinery.

Material Handling Equipment:

This includes conveyors, loaders, and other equipment for moving raw materials and finished products within the factory.

Remember, the specific requirements can vary based on the scale of production, the variety of products you plan to offer, and other factors such as local regulations, the target market, and the availability of raw materials. It’s also essential to consider the layout of your plant for efficient workflow and safety.

Consulting with a professional, like BORUI CABLE TIE MOLDS who has experience in setting up manufacturing plants will be beneficial. They can provide insights into the most reliable brands and the latest technology that could enhance efficiency and product quality.